Radio-Controlled Car

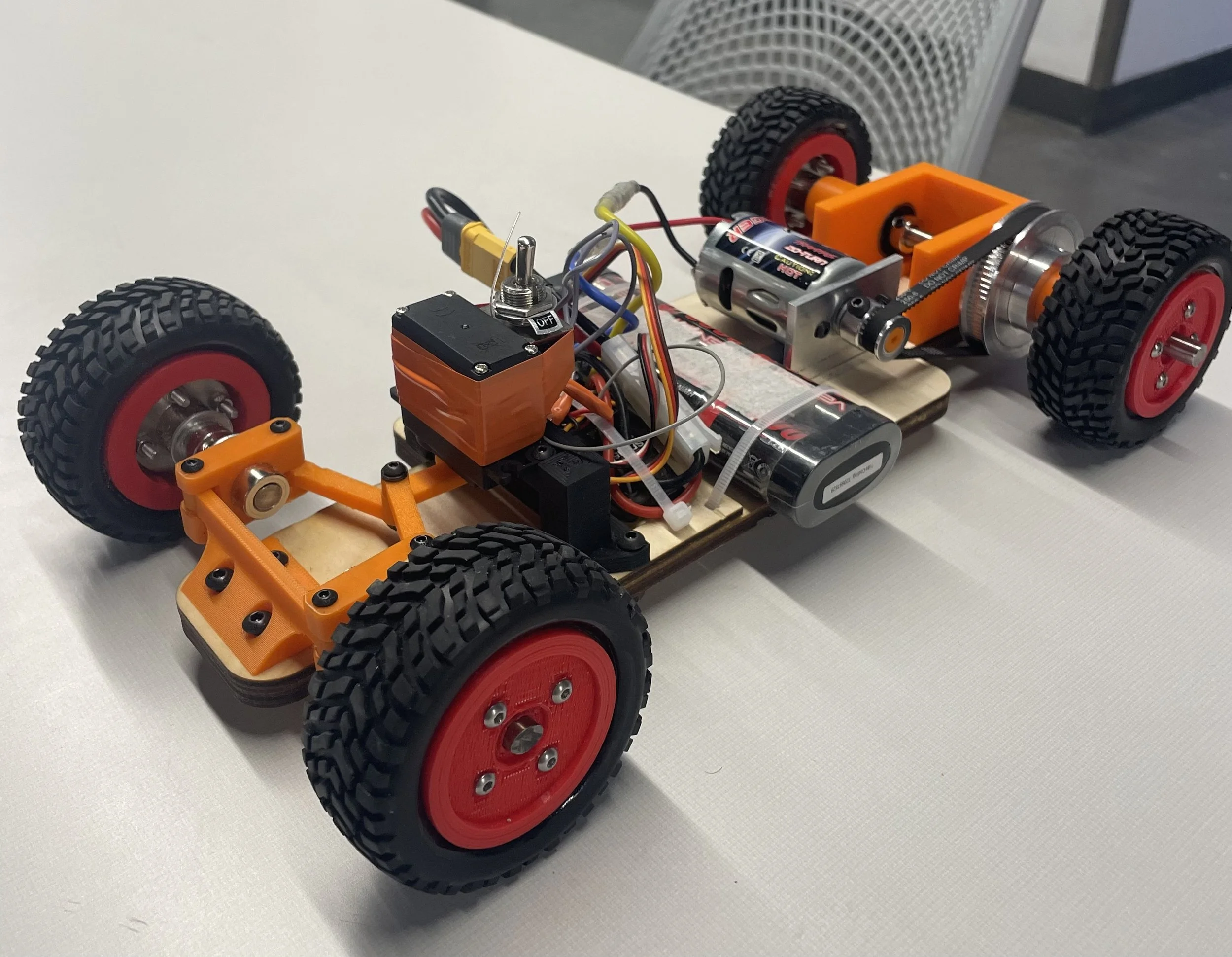

My team of five mechanical engineers designed an RC car from scratch to compete in a drag race between all of the Machine Elements classes. My roles through this project were design, manufacturing, and assembly.

Steering System

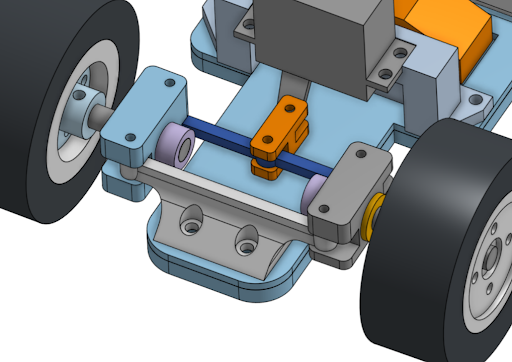

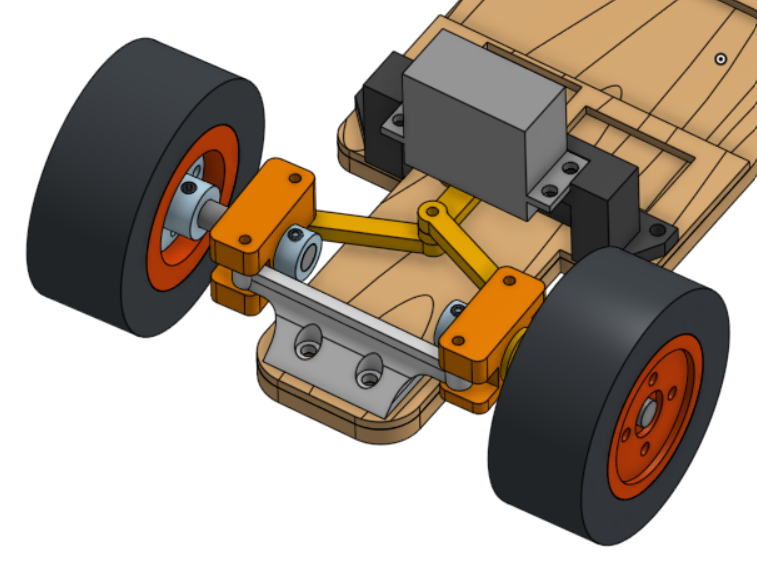

Used Ackerman steering geometry in our design to ensure a small turn radius and give us an advantage on the track.

Our first steering design proved ineffective. The wheels wouldn’t turn more than a few degrees in either direction.

We determined that there was one link too many via Grashof’s Equation, and redesigned the steering to remove the center link connecting the servo arm to the turning bone.

Design Elements

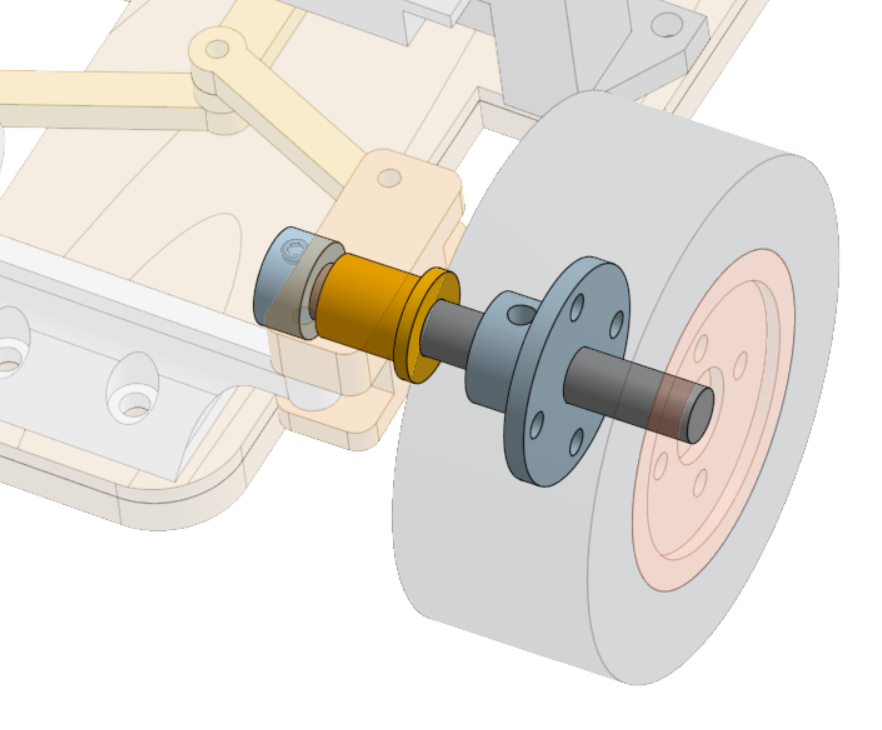

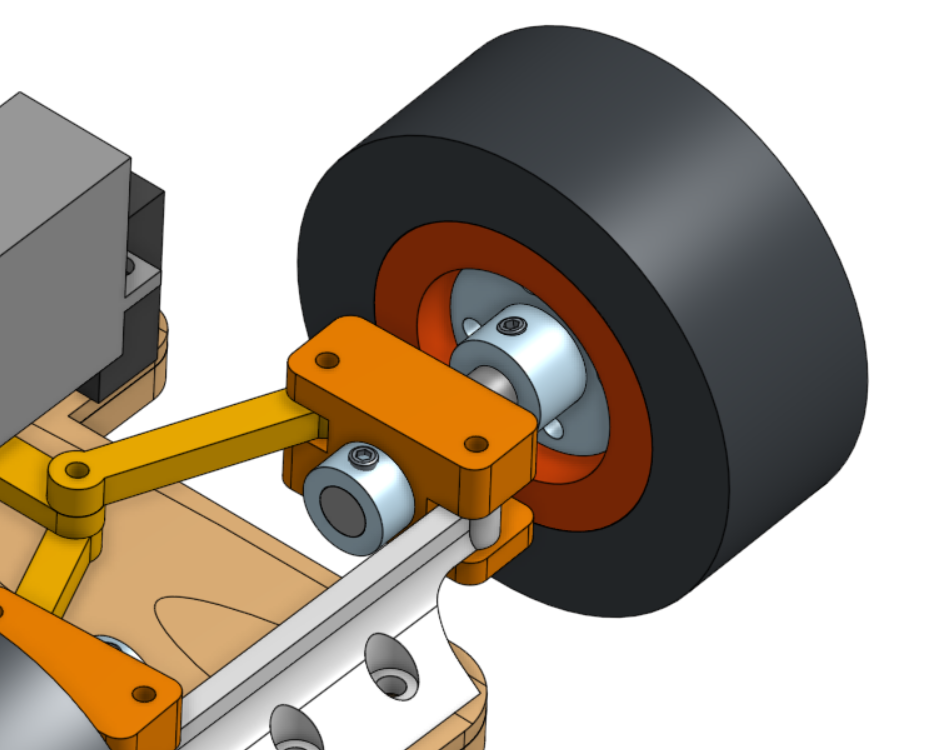

Since we used two small axles in the steering system, finding a way to keep them aligned was a top priority. We knew that deformation in the mounting blocks due to the axle would be a problem, since the blocks are 3D printed and we had a high speed metal rod spinning through it. Reducing friction was another concern; we wanted to use bearings but were constrained by the size of our axle mounts- bearings were too large to put in the mounting blocks.

Bushings were a perfect solution; they had a smaller outer diameter than bearings so they would fit in the blocks, provided a metal-on-metal contact to reduce friction, increased the surface area contact between the axle and mounting block by a few millimeters to provide slightly better alignment, and reinforced the axle holes in the mounting blocks to reduce chances of the hole becoming deformed.

Calculated the Torque-Speed Curve of the car and chose a 4:1 gear ratio to reduce the car’s speed to a manageable 17.9 m/s.

Full CAD Assembly

Steering Design V1

Steering Design V2

Steering Design V2 - in action

Bushings

Mounting Block